More efficient condensation

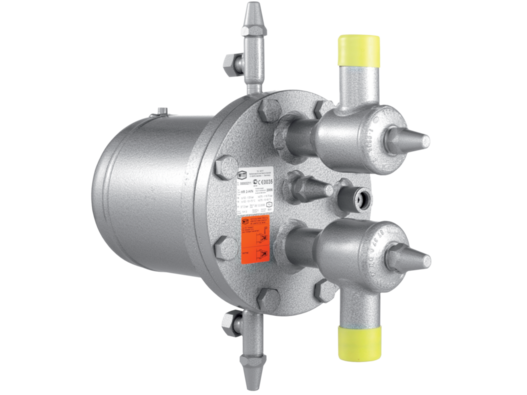

Pressure related expansion with WITT highside float regulators increases the efficiency.

Limited footprints, low installation costs and energy-efficient

components are the prerequisite for planning refrigeration systems today.

For the expansion of the condensed refrigerant it is often

observed in practice, that several condenser outlets are conducted via a

common pipeline to the expansion device.

However, in order to avoid performance losses in the condenser, this construction requires a high level of design and control effort.

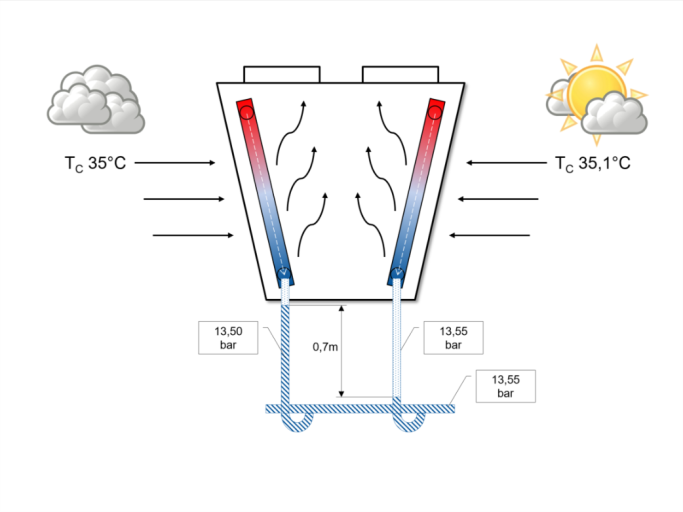

Condensers with several heat exchange coils connected in parallel

often work with a minimum of different condensation temperatures TC.

If a surface, for example, exposed to more intense sunlight, this causes a pressure difference at the outlets. Already

a deviation of the TC between the heat exchange coils of only 0,1K

causes an increase of approx. 0,7m pipework. These heights are often not available, so that a complicated and costly pipework and complex electrical control are the result.

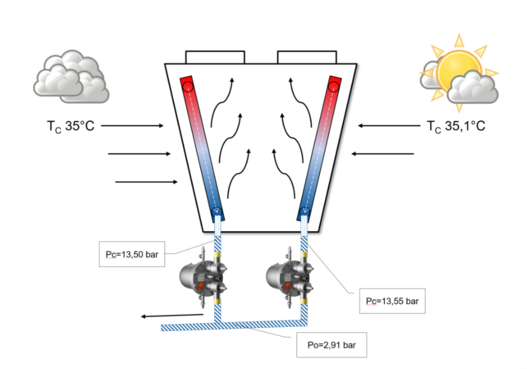

One float regulator per outlet recommended

Wijbenga B.V. in the Netherlands know the potential of WITT's high pressure float

regulators and consistently recommends one seperate device per

outlet of the condenser.

Wijbenga B.V. is one of the technological market

leaders for the development of industrial refrigeration solutions in

BeNeLux and sells WITT components and units.

Jeroen Schröer, Managing Director at Wijbenga tells in an interview:

"V-shape condensers use more space for condensation with the same footprint. Even with the noise emissions they have the advantage. In

addition there is a tax benefit in BeNeLux for condensers whose condensation

temperature TC deviates by max. 10K from the outside temperature. This is very easy to realize with WITT float regulators in combination with a V-shape condenser. Since you can use smaller float regulators then, there is hardly any difference in price. "

When asked what exactly the advantage of high-pressure float

regulators compared to electric expansion devices is, Mr. Schröer

answers:

"Despite

their compact design, the float regulators can contain a certain amount

of condensed refrigerant and thus reliably avoid backflow into the

condenser. They allow lower condensation temperatures and are maintenance free. This saves each 1K lower TC about 3% operating power. In addition, different condensation temperatures on the heat exchange coils can be neglected due to this design. Electronic expansion valves require either safe undercooling in the condenser or an extra high pressure receiver. The drive energy is also higher. "

Other large contractors of industrial refrigeration have also recognized the potential and are installing one WITT high-pressure float regulator in their refrigeration systems for each condenser outlet.